MR38-V8

Van Machinery

SWISS TYPE AUTOMATIC LATHE VAN MACHINE

We Offer You Precision Manufacturing Solutions Not Just A Machine

MR38-V8highlights

Van Makine cnc sliding automatons have many features for users, some of which can be listed as HFO Function, Oil Temperature and Number of Parts Display, Wired Handwheel and Improved Interface.

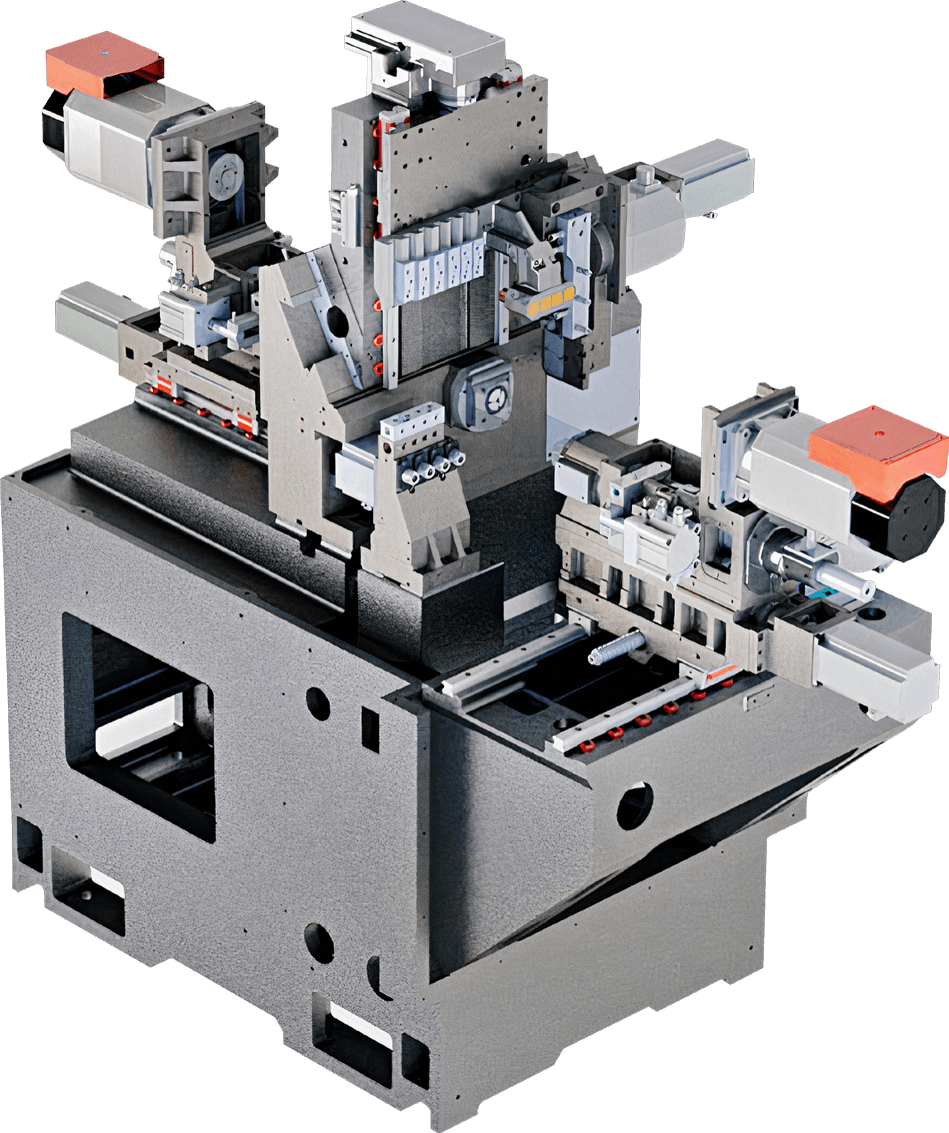

HIGH RIGIDITY MACHINE STRUCTURE

Maximum Rigidity, Long term Precision and best in class Complete with components PERFECT DESIGN

- 1

- 2

- 3

- 4

- 5

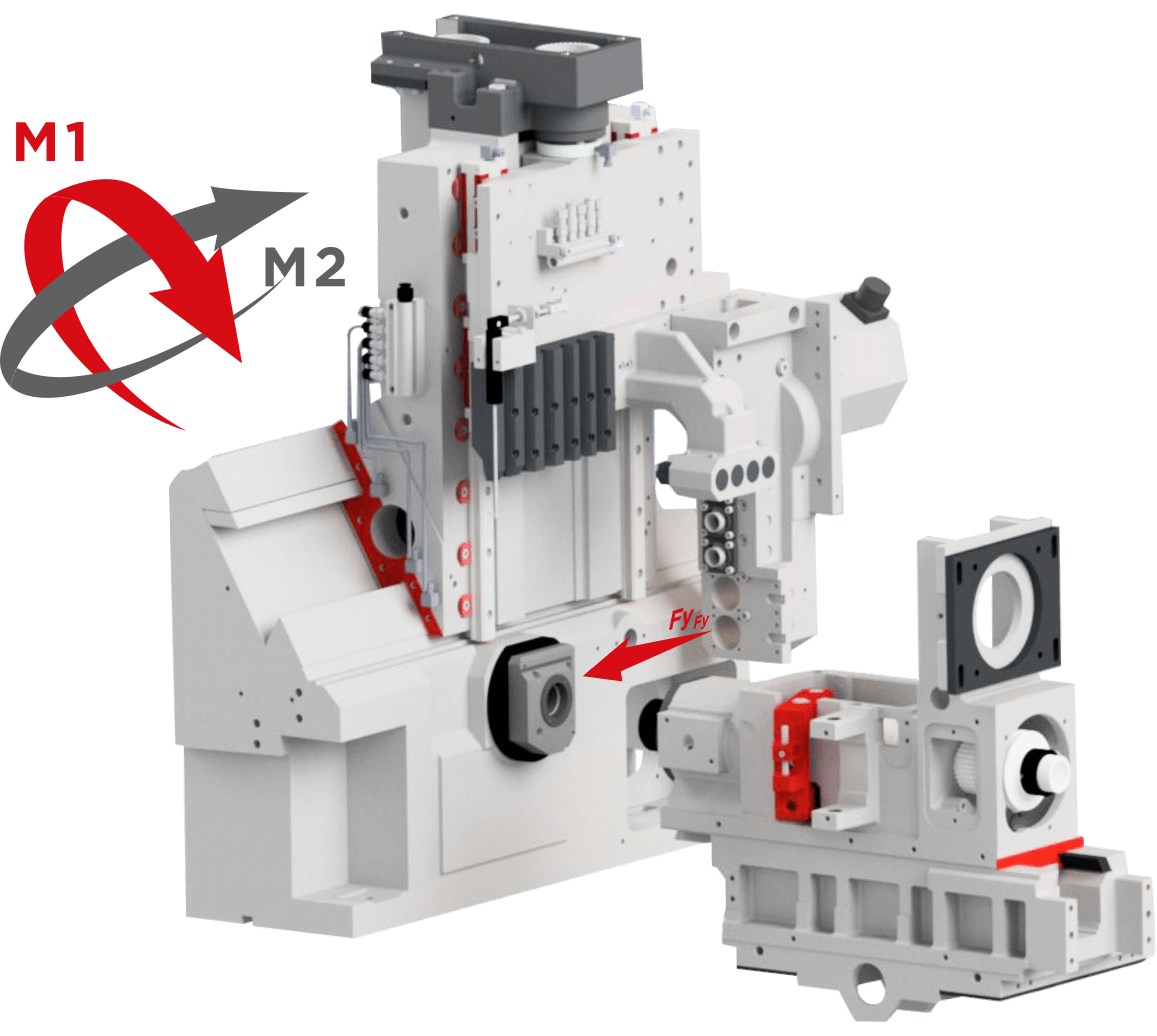

COMPARISON OF MOMENT LOADING OF SHEAR FORCES

Radial and axiel charges are shown. Here from horizontal and vertical skid systems 45° egic when compared with forces at least the cutting forces of the bank you'll see he's impressed.

- Slant type - My: 1

- Vertical type - My: 1,3

- Horizontal type - My: 1,9

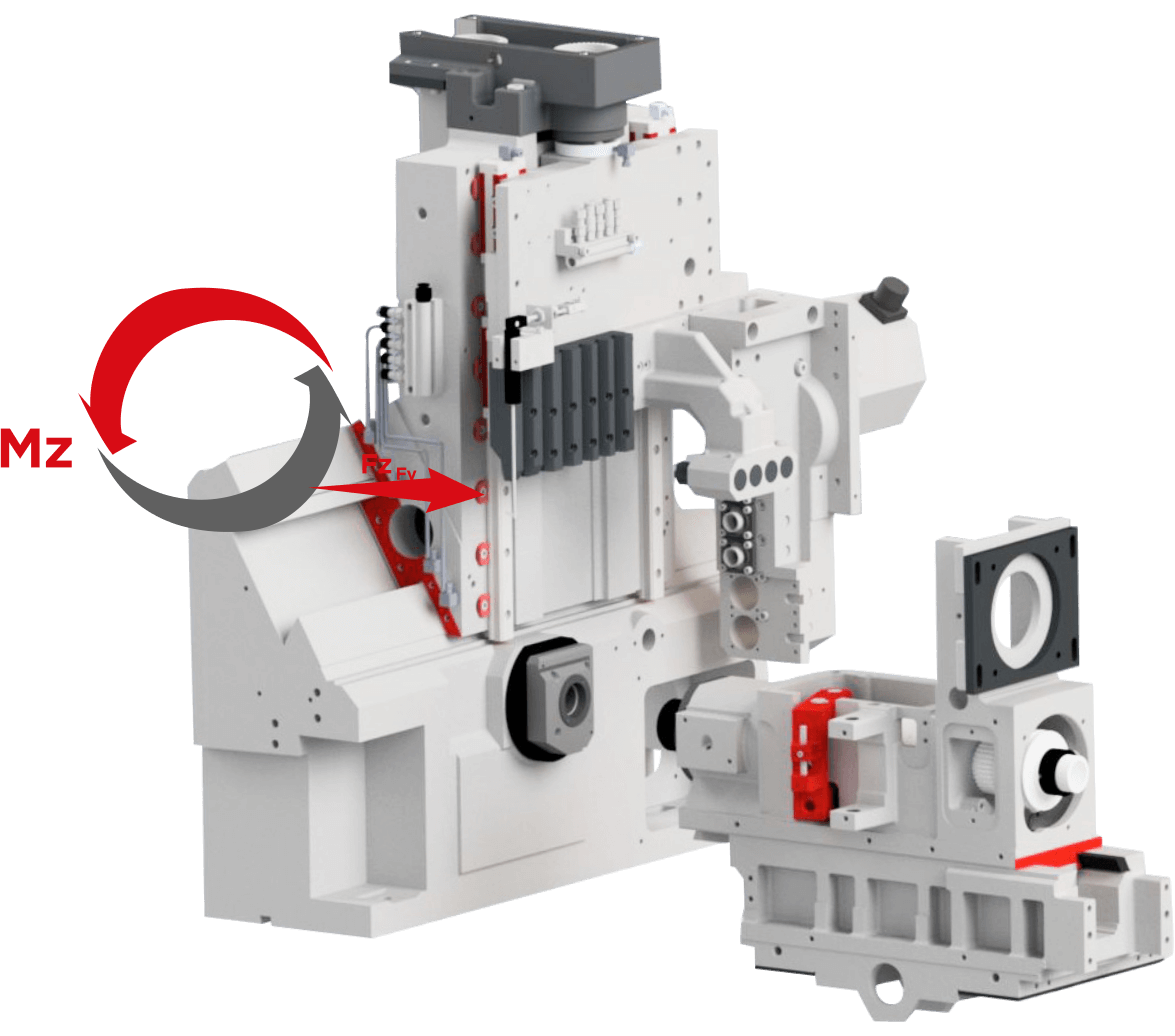

FZ OF THE PUSH FORCE MOMENT LOADING COMPARISON

As for the need force the moment load of the slant type is the smallest when compared to that of the vertical type and horizontal type.

- Slant type - Mz: 1

- Vertical type - Mz: 1,3

- Horizontal type - Mz: 1,5

Technicial Specifications

You can check the technical specification details of Van Makine cnc sliding automats for the specified model below.

- SPINDLE SPECIFICATIONS

- Maximum Machining Diameter 38 mm (NGB* 42 mm)

- Maximum Machining Lenght 320 mm (80 mm N.G.B.)

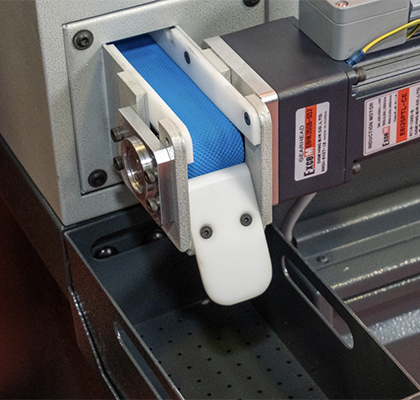

- Number Of Tools 5 pcs

- Radial Rotary Tools 5 pcs.(3 pcs. Std)

- Minimum Input Increment (0,001)

- Main Spindle Rotation 500-8,000 rpm

- Main Spindle Engine Power 11 kW (30 min. %60 ED) / 7,5 kW (Contiunous

- Rotarty Tool Rotation 6,000 rpm

- Engine Power Of Rotary Tool AC Servo 2.5 kW / 8 Nm

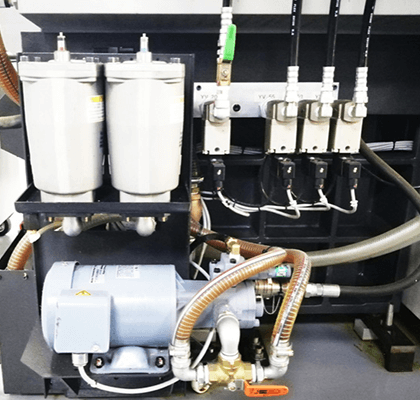

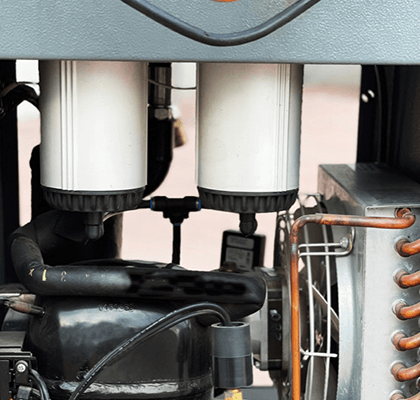

- Cooling Tank Capacity 250 L

- Coler Tank Motor 1,5 kW

- Power Comsuption 45 kVA

- Rapid Feed Rate 35,000 mm/dk.

- Fixed Tool Capacity

- Maximum Drilling Capacity 23 mm

- Maximum Threading Capacity M16 X P2,0

- Maximum Guide Capacity M16 X P2,0

- Rotary Tool Capacity

- Maximum Drilling Capacity 10 mm

- Maximum Guide Capacity M8 X P1,25

- Maximum Milling Capacity 10 mm

SPINDLE TECHNICAL SPECIFICATIONS

You can check the details of the spindle technical specifications for Van Makine cnc sliding automats for the specified model below.

- SPINDLE TECHNICAL SPECIFICATIONS

- Maxiumum Turning Diamaters 38mm (42 mm N.G.B.)

- Maxiumum Turning Leght 125 mm

- Maximum Number Of Tools 8 (döner tutucular ops.)

- Engine Power Of Sub Spindle 5,5 kW (30 dk %60 ED) / 3,7 kW (Contiunous

- Sub Spindle Rotation 8,000 rpm

- Rotary Tool Capacity

- Maximum Drilling Capacity 10 mm

- Maximum Threading Capacity M6 X P1,0

- Rotarty Tool Rotation 6,000 rpm

- Fixed Tool Capacity

- Maximum Drilling Capacity 14 mm

- Maximum Threading Capacity M12 X P1,75